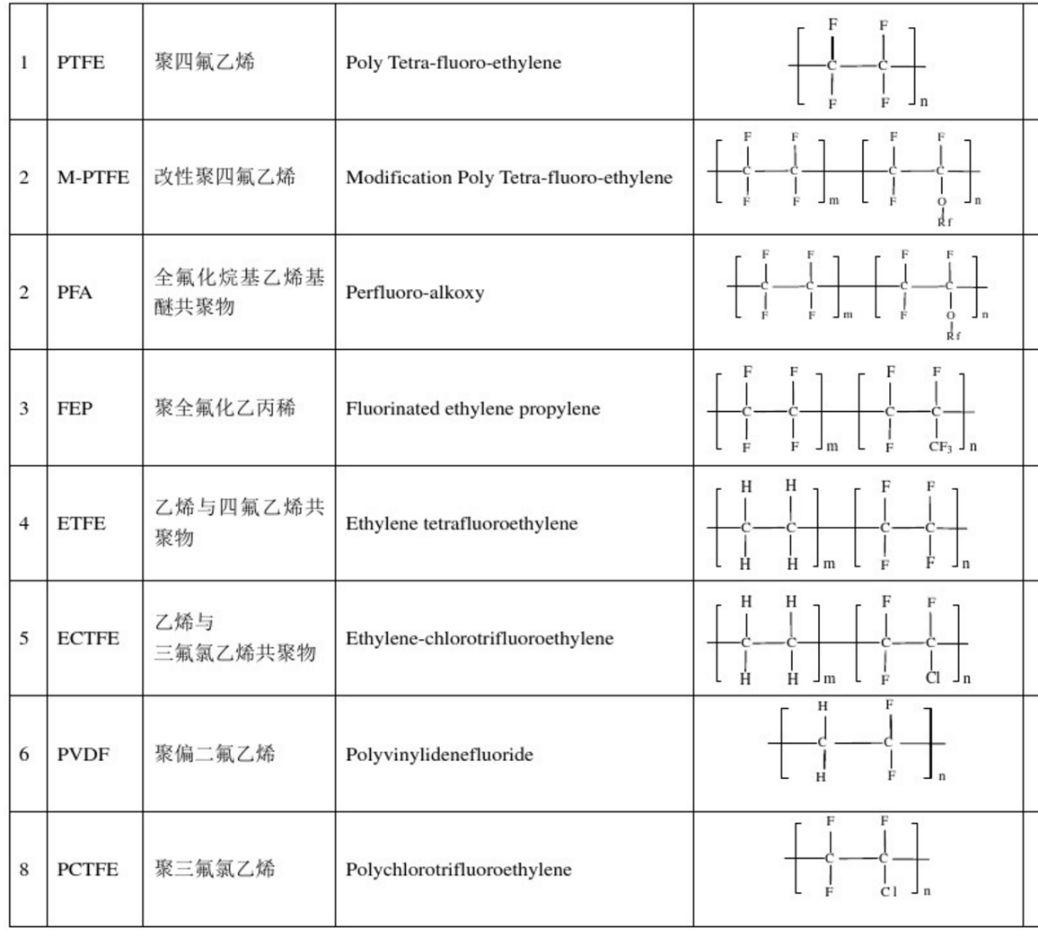

In addition to the well-known "king of plastics" polytetrafluoroethylene (PTFE) in the fluoroplastics family, the common fluoroplastics include PFA, FEP, ETFE, ECTFE, PVDF, PCTFE, etc., as shown in the figure below:

Here we summarize FEP in three sentences:

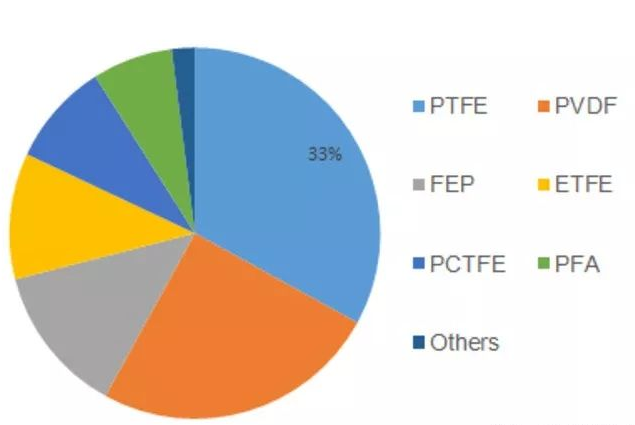

(1) FEP is the third most widely used fluoroplastics

Of course, PTFE is the most widely used fluoroplastics. After all, when it comes to fluoroplastics, the first reaction is PTFE, the second is PVDF, and the third is FEP. In front, I introduced the second PVDF of fluorine family (introduction of PVDF of fluorine material family). Today, I'd like to introduce you to FEP of fluorine family.

(2) FEP is copolymerized with tetrafluoroethylene and hexafluoropropylene

FEP is the abbreviation of perfluoroethylene propylene copolymer, commonly known as F46. FEP is the copolymerization of tetrafluoroethylene and hexafluoropropylene. The content of hexafluoropropylene is about 15%. It is a modified material of polytetrafluoroethylene.

(3) FEP has lower crystallinity, lower melting point and better processability than PTFE

In chemistry, structure determines properties, and structure affects crystallization. The simpler the chemical structure of the polymer chain, the higher the symmetry of the chain and the smaller the substituent, the more flexible the molecular chain will be and the easier it will be to crystallize. PTFE is a linear polymer with symmetrical structure, FEP is a branched polymer, so the crystallinity of FEP is not as high as that of PTFE, its processability is better than that of PTFE, and its melting point is lower.