Performance and usage:

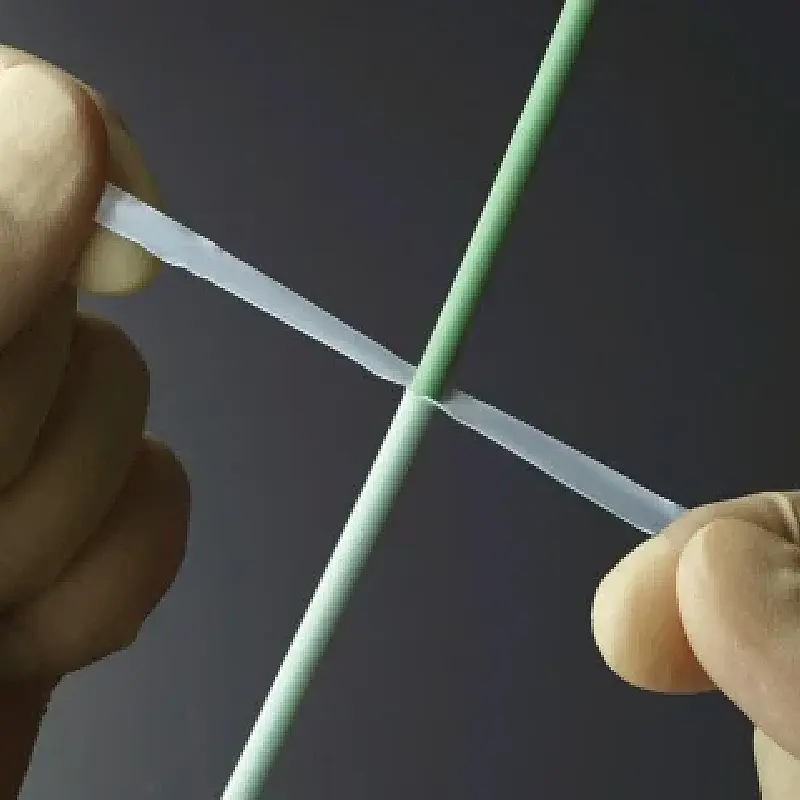

Polyperfluoroethylene propylene FEP medical peelable heat shrink tubing has excellent electrical insulation properties and high temperature resistance, and is used in

Components that need to be exposed to high temperature environments and have high insulation requirements during the process. Has excellent resistance to liquids and

Corrosive, physiologically inert, can be in direct contact with human skin, mainly used in surgical medical instruments and medical components and equipment.

Features:

Shrink ratio: 1.3:1

Working temperature: -55℃~200℃

Initial shrinkage temperature: ≥150℃

good transparency

Excellent electrical insulation properties and physiological inertness

Meets ethylene oxide (ETO), gamma sterilization

Compliant with ISO 10993-1

Environmental standards: no heavy metals, ROHS compliant

Standard color: transparent

Specification

|

No. |

Size |

ID before shrinking(mm) |

ID after shrinking(mm) |

Wall after shrinking(mm) |

|

1 |

XMC-FEP φ1.2mm |

>1.20 |

<0.70 |

0.20±0.05 |

|

2 |

XMC-FEP φ2.5mm |

>2.50 |

<1.80 |

0.20±0.05 |

|

3 |

XMC-FEP φ2.8mm |

>2.80 |

<2.10 |

0.25±0.05 |

|

4 |

XMC-FEP φ3.1mm |

>3.10 |

<2.20 |

0.25±0.05 |

|

5 |

XMC-FEP φ4.7mm |

>4.70 |

<2.90 |

0.25±0.05 |

Technical indicators

|

Item |

Test method |

Typical data |

|

Tensile strength(Mpa) |

ASTM D 638 |

≥13.8Mpa |

|

Elongation at break |

ASTM D 638 |

≥300% |

|

Axial shrinkage change rate |

ASTM D 2671 |

±10% |

|

Dielectric strength (kV/mm) |

ASTM D 2671 |

≥19.70 |

|

Insulation withstand voltage |

ASTM D 149 |

4000V, no breakdown in 60s |

|

Volume resistivity |

UL 224 |

≥101*Ω.cm |

|

Low temperature flexibility |

AMS-DTL-23053 |

65℃/4 hours, no cracks |

|

Copper corrosion |

AMS-DTL-23053 |

No dents or blackening |

|

clarity stability |

AMS-DTL-23053 |

pass |

|

Flame retardancy |

ASTM D 2671C法 |

Self-extinguishing within 15s |