What is FEP?

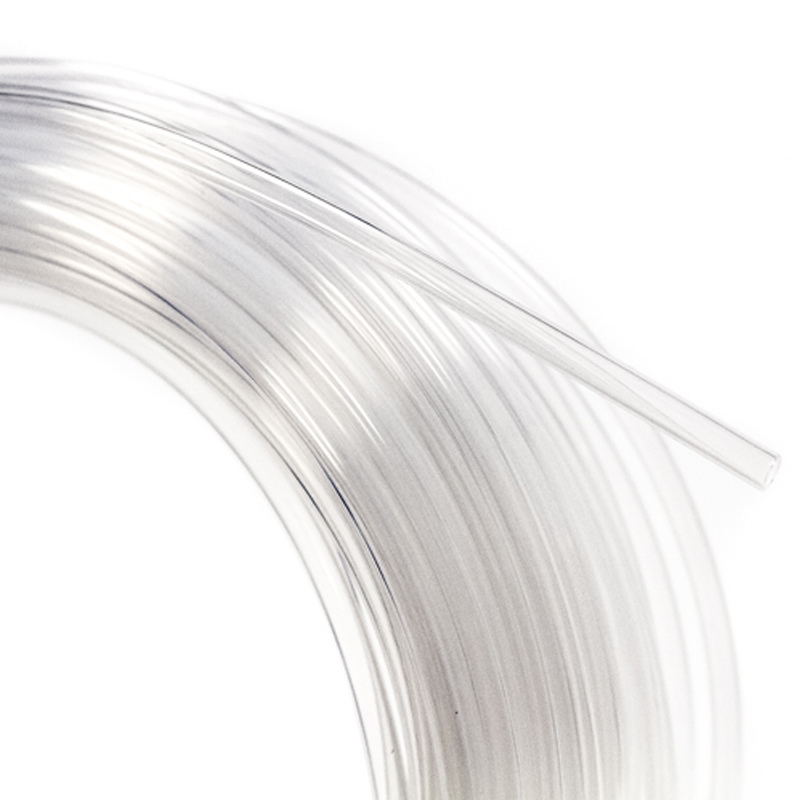

FEP tube stands for Fluorinated Ethylene Propylene Copolymer Tube. FEP is a type of special fluoropolymer plastic that boasts excellent chemical stability, temperature resistance, and electrical insulation properties. It's commonly used in the manufacturing of pipelines, fittings, coatings, and other high-performance applications.FEP tubes find widespread applications in various industrial sectors, including chemical processing, semiconductor manufacturing, pharmaceuticals, food processing, and more. They are used for conveying corrosive chemicals, high-temperature media, pure water, gases, and various other substances. Additionally, FEP tubes can be utilized for lining, coating, and sealing chemical equipment.

|

Advantages |

Description |

|

Excellent Chemical Stability |

Demonstrates remarkable corrosion resistance to a wide range of chemicals and solvents. |

|

High Temperature Resistance |

Maintains stability within the temperature range of -200°C to +204°C, suitable for extreme temperature environments. |

|

Outstanding Electrical Insulation |

Possesses strong electrical insulation properties, suitable for electrical and electronic equipment sectors. |

|

Transparency |

The tube material is transparent, allowing real-time observation of fluid inside, aiding in monitoring processes. |

|

Low Friction Coefficient |

Smooth surface with low friction coefficient, facilitating smooth flow of fluids inside the tube. |

|

Easy Processability |

Material is easily manufactured into various shapes such as pipes, fittings, films, etc., adapting to diverse application needs. |

|

Good Permeability and Gas Transmission |

Permits gas transmission through the material, applicable for gas transport and exhaust applications. |

|

Anti-Adhesive Property |

Surface is anti-adhesive, reducing impurity adherence and lowering the risk of pipeline blockages. |

|

Food-Grade Certification |

Certain FEP materials can meet food-grade certification requirements, suitable for the food and beverage industry. |

|

Excellent Weather and Aging Resistance |

Exhibits outstanding weather resistance and aging resistance for outdoor or long-term usage. |

|

Low Gas Emission and Volatility |

Shows low gas emission and volatility at high temperatures, suitable for high-temperature applications. |

Key Points for Purchasing FEP Tubes from China:

1.Find Reliable Suppliers:

Finding reputable and experienced suppliers in China is crucial. You can search online, attend industry exhibitions, and consult industry experts to identify suitable suppliers.

2.Quality Certifications and Credentials:

Ensure that the selected suppliers have necessary quality certifications and credentials. These may include ISO 9001 quality management system certification, food-grade certification (if applicable), ROHS certification, and others.

3.Sample Testing:

Before making a large-scale purchase, it's advisable to procure a small quantity of samples for testing. This will help you assess the quality, performance, and compliance of the products.

4.Clear Specifications and Requirements:

When communicating with suppliers, make sure to specify the requirements for the FEP tubes clearly, including specifications, dimensions, material, etc., to avoid misunderstandings or disputes later on.

5.Inquiries and Negotiations:

Request quotations from multiple suppliers to understand the price range in the market. Negotiate on aspects such as price, delivery time, payment terms, and other conditions to secure favorable terms.

6.Product Quality Inspection:

Consider sending a representative to conduct product quality inspections before the goods are shipped to ensure they meet your requirements.

7.Contracts and Payments:

Establish a clear purchasing contract that outlines product specifications, quantities, prices, delivery dates, and other terms. The contract should also address solutions for quality issues and breach of contract. For payments, consider staggered payments to align with the delivery process.

8.Transportation and Logistics:

Ensure you have a clear logistics arrangement with the supplier, covering transportation mode, shipment time, freight charges, insurance, and other logistics aspects.

9.Customs and Tax Matters:

Familiarize yourself with China's import and export regulations and tax policies to avoid customs and tax-related issues.

10.Cultural and Language Differences:

When communicating with Chinese suppliers, consider cultural and language differences to ensure mutual understanding and prevent misunderstandings.

How to ensure quality in advance?

YOZONETECH will provide accurate sizes and sufficient quantities of free samples according to customer requirements to ensure the reliability of test results. We have a large inventory to ensure the delivery of samples or finished products.

Applications of FEP Tubes:

1.Chemical Industry:

FEP tubes are used in the chemical industry to convey corrosive chemicals, solvents, acids, and bases. Their exceptional corrosion resistance makes them ideal for piping materials.

2.Semiconductor Manufacturing:

FEP tubes are employed as chemical transport lines in semiconductor manufacturing processes. Their high purity and low contamination features suit cleanroom environments.

3.Pharmaceutical and Life Sciences:

FEP tubes are used to transport drugs, reagents, and biochemical substances in the pharmaceutical and life sciences sector. They don't adversely affect medications and biomaterials.

4.Food Processing:

Certain food-grade certified FEP tubes are used in the food processing industry for conveying food and beverages.

5.Electronics and Electrical Engineering:

FEP tubes, owing to their excellent electrical insulation properties, are used for cable protection sleeves, wire insulation, cable harnesses, and more.

6.Chemical Equipment Coatings:

FEP materials are employed to create linings, coatings, and seals for chemical equipment, providing additional corrosion resistance.

7.Environmental Equipment:

FEP tubes are used in gas processing and exhaust systems in environmental equipment due to their corrosion resistance and temperature tolerance.

8.Aerospace and Automotive Industry:

FEP tubes are used in aerospace and automotive industries for fuel transport, hydraulic systems, and fluid conveyance in high-temperature environments.

9.Chemical Sensors and Instruments:

FEP tubes play a crucial role in chemical sensors, laboratory instruments, and research equipment for chemical substance transport.

10.Coating and Spray Painting:

FEP tubes are used in the coating and spray painting industry, with their chemical resistance and high-temperature capabilities suitable for conveying paints and coatings.

The relevant parameters of FEP tubes

|

Parameter |

Value Range or Example Values |

|

Inner/Outer Diameter |

1/8" - 6" (0.125" - 6.0") |

|

Wall Thickness |

0.010" - 0.500" (0.25mm - 12.7mm) |

|

Length |

1 ft - 20 ft (0.3m - 6.1m) |

|

Diameter Tolerance |

±0.005" (±0.13mm) |

|

Thickness Tolerance |

±10% |

|

Length Tolerance |

±1% |

|

Temperature Range |

-200°C to +204°C (-328°F to +399°F) |

|

Pressure Rating |

Up to 150 psi (10.34 bar) |

|

Bend Radius |

Minimum of 1" (25.4mm) |

|

Minimum Bend Diameter |

3" - 6" (76mm - 152mm) |

|

Color |

Transparent, white, black, blue, red, etc. |

|

Surface Treatment |

Smooth, no texture, no scratches, etc. |

|

Transparency |

Transparent or translucent |

FEP Tube - Processing Techniques

1.Extrusion:

FEP resin is heated and forced through a die to form the desired tube shape. This is a common method for producing FEP tubes of various sizes.

2.Heat Shrink Tubing:

FEP heat shrink tubing is heated to shrink down and conform to the shape of the object it's covering, providing insulation, protection, or sealing.

3.Coiling and Bending:

FEP tubes can be coiled or bent to achieve specific shapes or routing in applications where flexibility is required.

4.laring:

The end of a FEP tube can be flared to facilitate connections with other components, such as fittings or connectors.

5.Cutting and Welding:

FEP tubes can be cut to specific lengths and welded together to create complex structures or longer tubing runs.

6.Lining and Coating:

FEP can be used to line or coat other materials, providing a protective barrier against corrosion or chemical attack.

7.Printing and Labeling:

Information, identification, or branding can be printed or labeled onto the surface of FEP tubes for easy identification.

8.Surface Treatment:

Surface treatments can be applied to improve properties like adhesion, lubricity, or anti-static behavior.

☛ Learn More

Yozonetech FEP, PFA and PTFE tube Website ➤ https://www.chinaptfetube.com/

Facebook ➤ https://www.facebook.com/ChinaFEPtube

LinkedIn ➤ https://www.linkedin.com/company/chinaptfetube/

YouTube ➤ https://www.youtube.com/channel/UCWzNjAgghr0B7tXDrP_jwfA

--------------------------------------------------------------------------

☛ Enquiry Service:

Email : [email protected]

WhatsApp: wa.me/008613752771911