Heat shrink tubing, a critical component for insulation and protection of wires and connections, has become an indispensable element in various sectors from automotive to electronics. Navigate through this year's standout trends in the heat shrink tubing assortments and learn why YOZONE has become a byword for quality and innovation.

Aesthetic differentiation is just the tip of the iceberg. In a sea of cables and connections, coloured heat shrink tubing isn't just about customization – it's about efficiency. YOZONE's diverse range of hues doesn't just brighten up the space, but also provides quick identification for faster repairs and installations.

In an era where electronics are shrinking, the need for miniature heat shrink tubing skyrockets. YOZONE addresses this trend by supplying slim, resilient tubing options for the ever-decreasing space on PCBs and in tiny devices.

For applications that require something in between – not too large, not too small – YOZONE's 6mm heat shrink tubing presents the perfect middle ground. Its versatility makes it a popular choice across industries, epitomizing the company's commitment to meeting diverse needs.

YOZONE isn't just another heat shrink tubing manufacturers. It's a trendsetter redefining the standards of insulation technology. This article delves into how YOZONE's dedication to quality and innovation has set the pace for the industry's future.

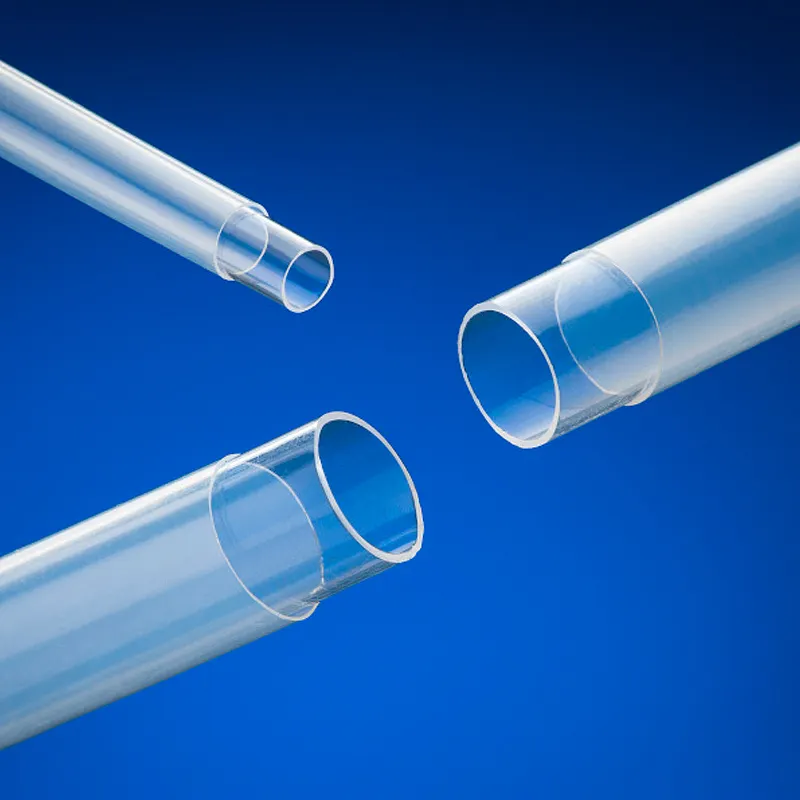

As we narrow in on YOZONE's product parameters, their commitment to quality is evidenced by the use of 100% virgin PTFE & FEP pipe material. This choice reflects not only an adherence to high standards but shows a partnership with leading material producers like DAIKIN and DUPONT. The customization options YOZONE offers in length and thickness enable a bespoke approach to every project's needs.

Plus, with colors crafted to either showcase transparency or embrace the shadow with black tubing designed to conceal product details, YOZONE provides strategic aesthetic choices that align with our customers' objectives.

When it comes to tolerances, YOZONE demonstrates precision with a ±0.05 mm margin, ensuring snug insulation every time. Their remarkable tensile strength that can reach 10.4Mpa, and a vast operating temperature range from -200 to 205°C, manifest YOZONE's dedication to high-performance products capable of withstanding diverse environmental challenges.

Moreover, the tubing's stability across most mediums due to exemplary chemical resistance, paired with superior electrical insulation properties, mark it as a front-runner in the market. YOZONE's commitment to safety and quality is also made clear by the bouquet of certifications they have earned, including UL, CE, FDA, ROHS, REACH, and upholding the ISO9001:2008 standard.

Every item from YOZONE is a testimony to their relentless pursuit of excellence, having passed stringent SGS tests, further cementing their reputation as a trustworthy leader in the heat shrink tubing industry.

YOZONE Heat Shrink Tubing finds applications in various industries, where its superior insulation properties play a vital role. Some common applications include:

Electronics and Electrical: YOZONE Heat Shrink Tubing provides effective insulation for electrical components, preventing electrical leakage and ensuring safety. It is widely used in the manufacturing of cables, connectors, and wiring harnesses.

Aerospace and Automotive: In industries where extreme temperatures, vibrations, and harsh environments are prevalent, YOZONE Heat Shrink Tubing acts as a protective barrier for wires, cables, and hoses. It offers excellent resistance to chemicals, fuels, and solvents, making it ideal for aerospace and automotive applications.

Medical and Pharmaceutical: YOZONE Heat Shrink Tubing is widely used in medical devices and pharmaceutical equipment due to its biocompatibility and resistance to sterilization processes. It ensures the integrity and insulation of sensitive components in these critical applications.

Industrial and Manufacturing: YOZONE Heat Shrink Tubing is a go-to solution for insulation in heavy-duty industrial equipment, machinery, and pipelines. Its resistance to extreme temperatures and chemicals makes it ideal for applications in oil and gas, mining, and manufacturing industries.

Heat shrink tubing is classified based on various factors. Actually, referring to types of heat shrink tubing, we must consider about its material composition, shrink ratio, or application. For satisfy different customers’ demand, there is the types list below:

Polyolefin Heat Shrink Tubing: This is the most common type of heat shrink tubing. It is made from a polymer called polyolefin, which offers excellent electrical insulation and chemical resistance. Polyolefin tubing is widely used in electronics, automotive, and general-purpose applications.

PVC Heat Shrink Tubing: PVC (Polyvinyl Chloride) heat shrink tubing is known for its flexibility and durability. It provides good electrical insulation and is commonly used in cable and wire harnessing, as well as electrical insulation in low voltage applications.

Fluoropolymer Heat Shrink Tubing: Made from materials such as PTFE (Polytetrafluoroethylene) and FEP (Fluorinated Ethylene Propylene), fluoropolymer heat shrink tubing offers exceptional resistance to chemicals, high temperatures, and extreme environments. It is often used in aerospace, automotive, and industrial applications where harsh conditions are present.

Silicone Heat Shrink Tubing: Silicone heat shrink tubing is known for its flexibility and high-temperature resistance. It can withstand a wide range of temperatures and provides excellent electrical insulation. Silicone tubing is commonly used in medical, electrical, and industrial applications.

2:1 Shrink Ratio: This type of heat shrink tubing shrinks to half of its original diameter when heated. It provides good insulation and is suitable for applications where a moderate level of protection is required.

3:1 Shrink Ratio: With a higher shrink ratio, this tubing shrinks to one-third of its original diameter. It offers better insulation and is often used in applications where a higher level of protection is needed.

4:1 Shrink Ratio: This tubing provides the highest level of shrinkage, reducing its diameter to one-fourth of its original size. It offers excellent insulation and is commonly used in applications that require maximum protection and strain relief.

Single Wall Heat Shrink Tube: It is available in various materials such as polyolefin, PVC, and silicone, offering different levels of flexibility, temperature resistance, and electrical insulation properties. The shrink ratios for single wall tubing typically range from 2:1 to 4:1, providing a moderate level of shrinkage and insulation. Additionally, it is easy to use, cost-effective, and versatile, making it suitable for a wide range of applications. It is commonly used in industries such as electronics, automotive, telecommunications, and electrical installations.

Dual-Wall Heat Shrink Tubing: This type of tubing consists of an inner layer that provides insulation and an outer layer that offers protection and sealing. Dual-wall tubing is commonly used in applications where moisture resistance and environmental sealing are required.

Adhesive-Lined Heat Shrink Tubes: Adhesive-lined tubing has an inner layer of adhesive that provides a secure and watertight seal when heated. It is often used in applications that require moisture resistance and environmental sealing.